Home ![]() TOLL PROCESSING

TOLL PROCESSING

Toll processing

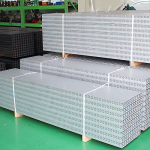

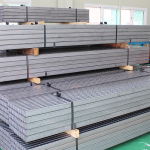

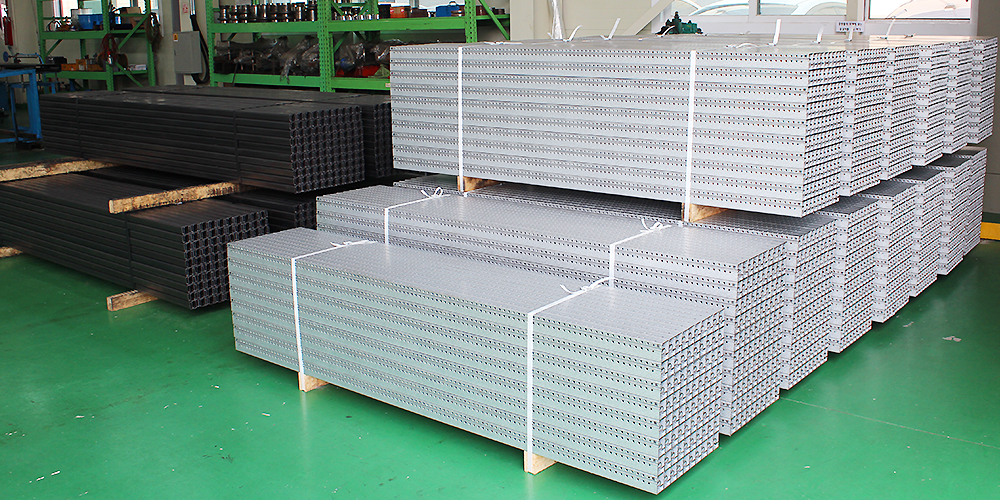

Professional Quality for the Best Performance

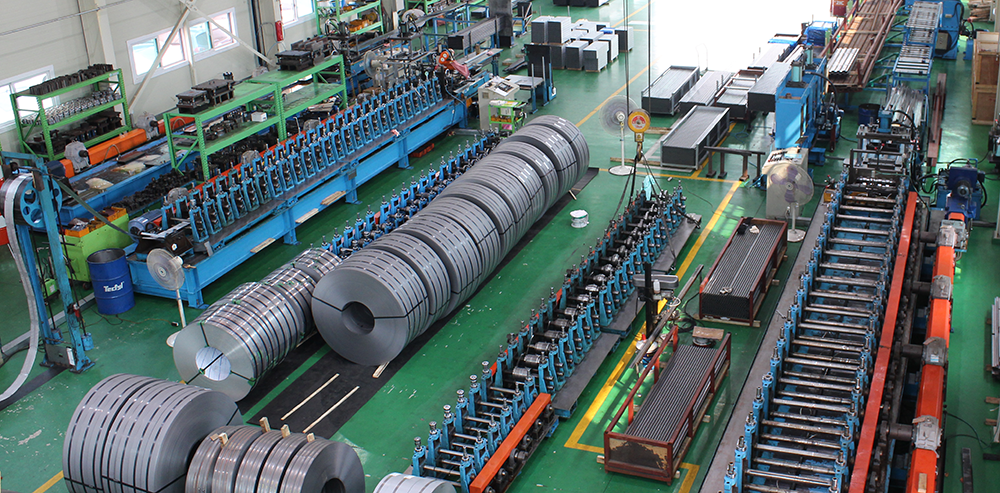

We, Roll forming company limited, have our own Roll forming line to demand from customers and our professional staff members are constantly engaged in research and development.

You are fully satisfied with our productive capacity, technology application and immediate response.

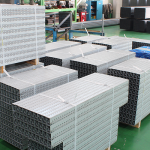

The specification of Roll forming line

| Line No. 1 | |

| Thickness of coil | 0.8mm ~ 3mm |

| Width of coil | 30mm ~ 410mm |

| Length of product | 300mm ~ 10,000mm |

| The Number of roll stage | 25 |

| Line No. 2(SAW Cutting) | |

| Thickness of coil | 0.8mm ~ 3mm |

| Width of coil | 30mm ~ 410mm |

| Length of product | 300mm ~ 10,000mm |

| The Number of roll stage | 25 |

| Line No. 3 | |

| Thickness of coil | 0.8mm ~ 2mm |

| Width of coil | 30mm ~ 220mm |

| Length of product | 300mm ~ 10,000mm |

| The Number of roll stage | 18 |

| Line No. 4 | |

| Thickness of coil | 1mm ~ 2mm |

| Width of coil | 500mm ~ 730mm |

| Length of product | 1000mm ~ 20,000mm |

| The Number of roll stage | 25 |